A common question that appears both online and in educational settings is “What is the difference between prestressed and reinforced concrete?”. PCI houses a variety of information discussing this subject in their technical document section. Below is a brief overview of what those technical documents highlight.

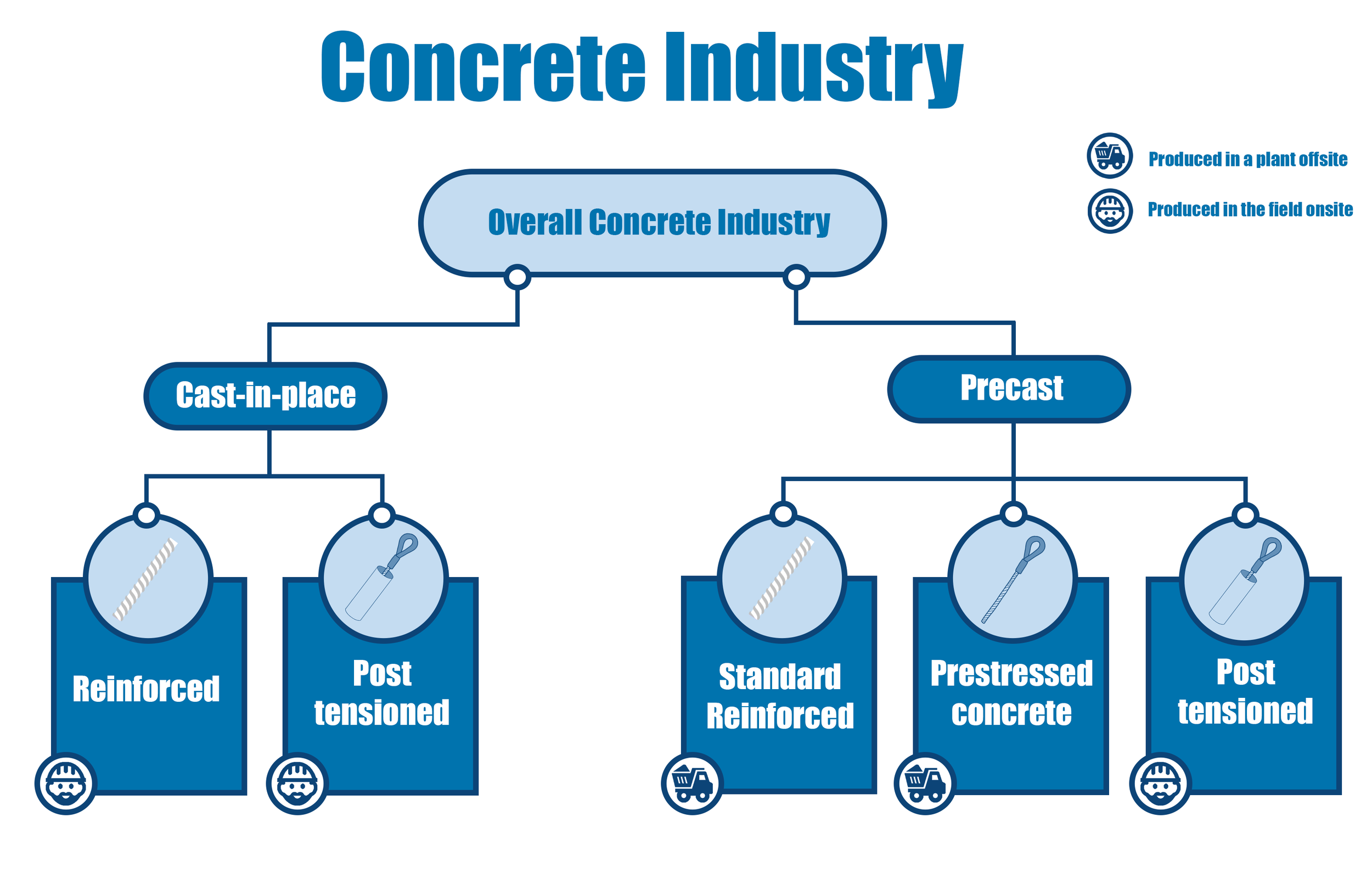

Reinforced concrete is just one segment of the concrete industry. Within the reinforced concrete segment is the product of precast concrete, and within that subsection is a type of reinforcing referred to as prestressed concrete.

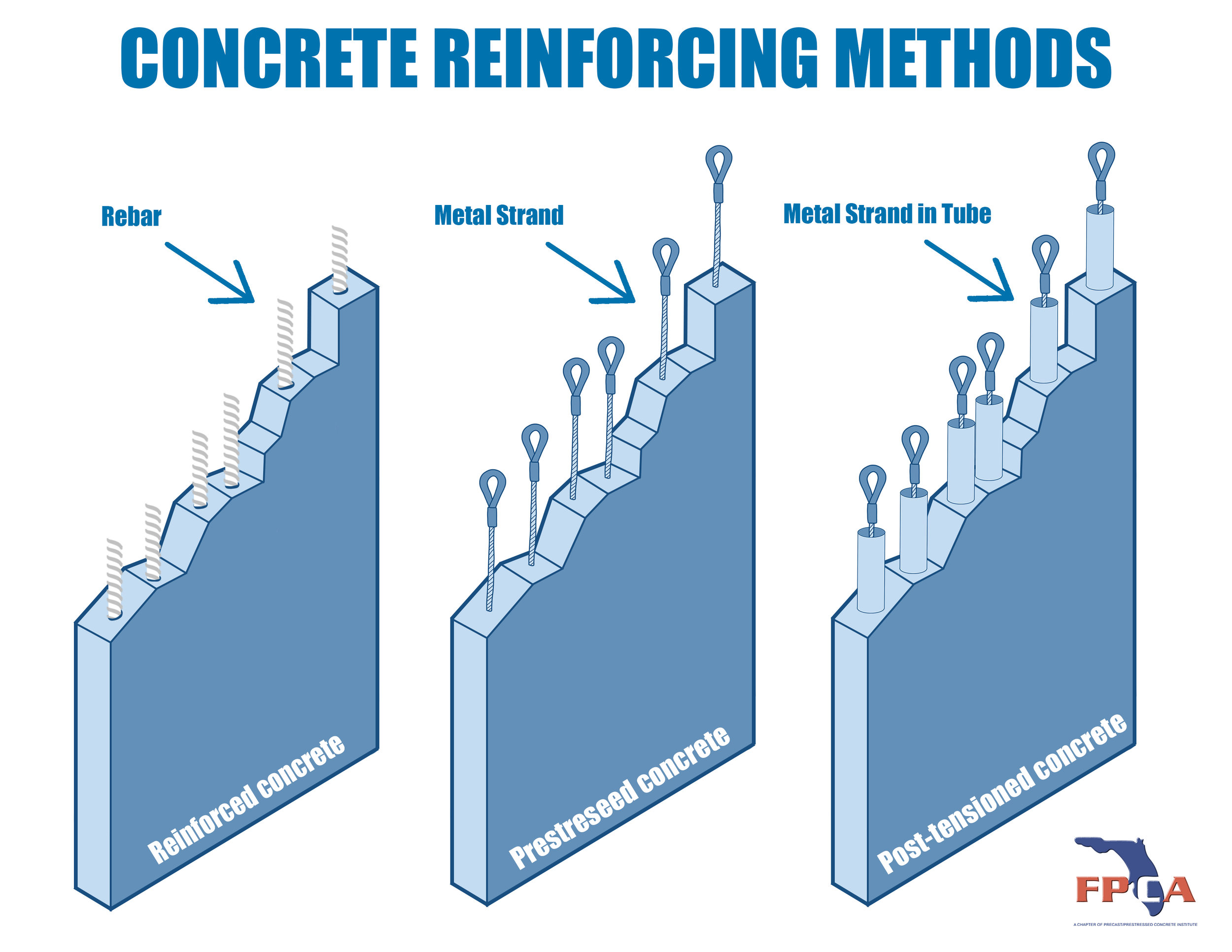

Prestressed concrete comes from the primary reinforcing method which uses a type of wire called strand (seven wire wrap) instead of deformed rebars. The wire is placed under tension, which is pre-applied, in order to provide a load carrying force to the concrete from the beginning of its formation. This is different from post-tensioned concrete where a similar tension is applied to the concrete but toward the end of construction of the frame it is a part of in the field. Prestressed concrete also differs from reinforced concrete because the reinforcement comes from external loads and does not have any inherent proactive role.

PRECAST 101 SERIES WHAT IS PRESTRESSING?

Lenny Salvo from Coreslab Structures of Orlando, a PCI certified precast plant, describes prestressed concrete in this way:

“Like most other types of long span structural concrete members, prestressed concrete is asymmetrically reinforced. Because of that, one effect of prestressing causes all (except for very short length pieces) to have camber (crown running along the length) which sometimes can be significant. This lack of symmetry creates compression in the lower flange and tension in the upper flange when the member is at rest and not loaded. This tension/compression flange orientation will often continue to be the case until an applied load representing a fair percentage of the unit capacity is being carried. Compare that against plain reinforced concrete and the difference is clear.”