As a high-performance construction material, precast concrete combines readily with other systems. It naturally offers the versatility, effectiveness, and resilience needed to satisfy the long-term demands of high-performance structures and the requirements for multiple hazards.

Architectural Precast and Versatility

Any building type can employ architectural precast concrete as a masonry structural component for feature trim, ornament, cladding, veneer, or face. High-performance architectural products are produced via the controlled production of precast concrete panels.

The Church of Latter Day Saints Temple is an excellent example of how precast can be used to create a versatile yet high-performance facade with architectural elements. The 41-foot central precast spire was manufactured using a light-colored, acid-etch finished precast facade meant to resemble the natural stone used on other temples in the US.

Architectural Precast and Efficiency

Continuous insulation, a continuous air barrier, and a vapor retarder can all be effectively combined into one precast concrete panel. A panel can also incorporate multiple finishes. This lowers the risk of incorrect installation of these crucial building enclosure components and the complexity of the construction and detailing.

Precast concrete also saves time and money and lessens the possibility of change orders because of winter weather. It arrives at the site prepared for installation and does not need protection from rain, sun, snow, wind, or severe temperatures. One of the quickest building techniques available is precast concrete, produced offsite to minimize disruption to the project site and maximize quality.

Precast wall panels have weather-tight enclosures for the best mold and mildew defense. Because of their higher structural strength, they are highly impact and explosion resistant for the highest level of security. Due to their durability, these wall panel systems are the best option for satisfying long-term construction needs.

Architectural Precast Offers Unlimited Aesthetics

Precast concrete architectural facades have been famous among architects for more than 50 years due to their remarkable aesthetic and structural diversity, quick enclosure time, and durability. No other material offers various forms, hues, and textures, in addition to fire protection, acoustic insulation, weatherproofing, high durability, low maintenance requirements, and quick enclosure.

The Hospital Winter Garden campus challenged precasters to develop a unique basket weave pattern that was to be installed on both the interior and exterior of the structure. Using a customer formliner meant that each basket weave piece was perfect to complete the pattern and provide the visual interest the owner was looking for.

Photo via GATE Precast Company

Precast offers various aesthetic alternatives, whether your project has to stand out from the crowd or blend in with the surroundings. Precast can imitate, embed, or veneer conventional materials and is available in virtually any color, shape, and texture. Additionally, many finishes can be combined into a single panel with precast concrete wall panels without flashing or additional details, which saves time and money.

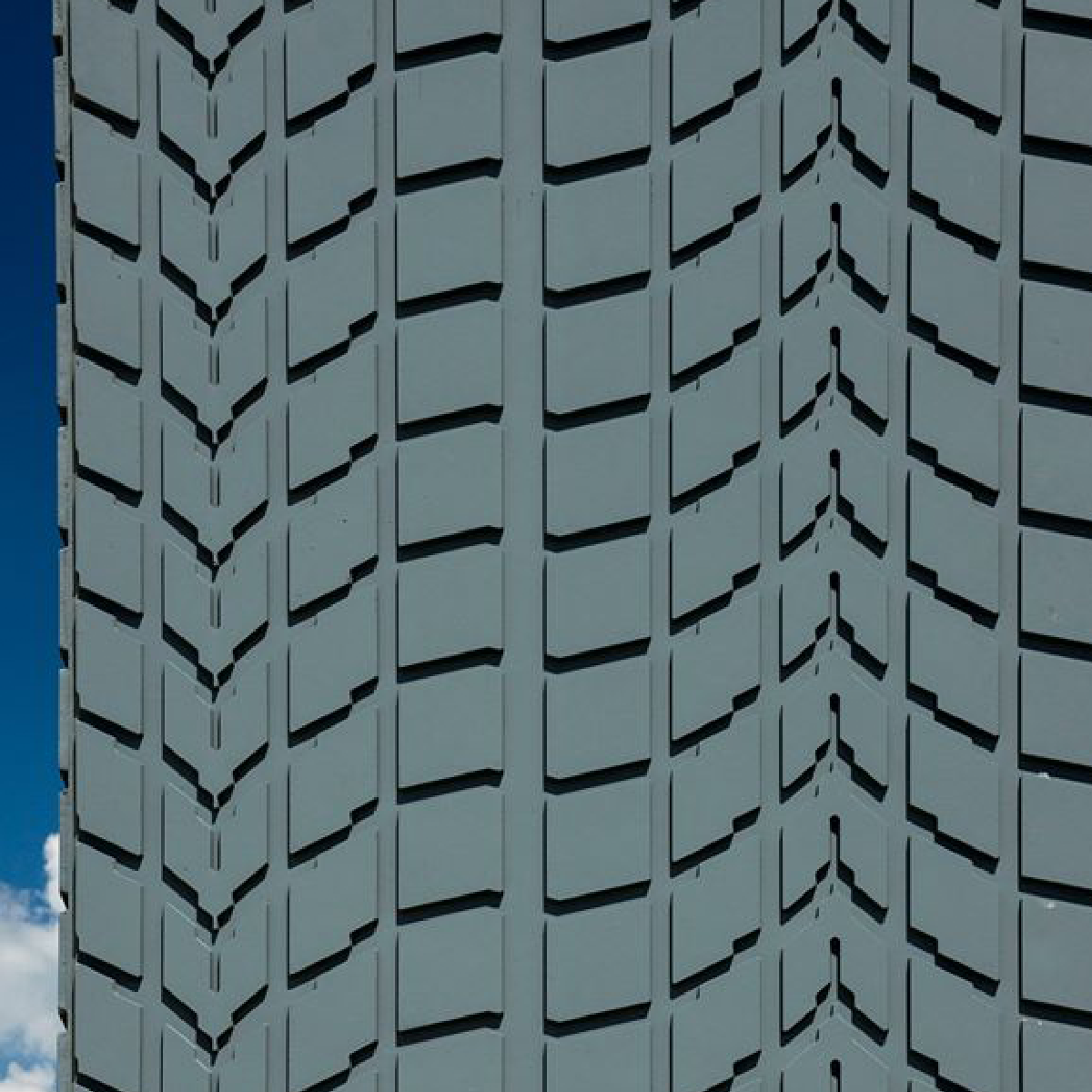

Photo via Rich Montalbano / RiMO Photo LLC and Gate Precast Company

The FIU Academic Center wanted a distinctive look to its campus’s central building. The unique “fin” look was designed initially as metal pieces, but after it was discovered that precast concrete could achieve the same look while maintaining the hurricane resistance needed, the designer decided to go with precast.

Two Types of Architectural Precast Panels

Architectural precast panels can come in two varieties, offering different benefits.

Insulated Panels

Insulated panels serve as a barrier solution that offers a face-sealed water barrier and thermal efficiency. You can obtain a textured accent for any design appearance, insulation that complies with more strict construction code standards, and a back concrete wall with a sealed completed wall with three layers of cohesion.

The interior face and exterior walls of the Cascades Mixed Use structure are exposed concrete to provide an industrial loft-style appearance. These walls are insulated, load-bearing precast walls that have been integrated with colored concrete, sandblast finishes, reveals, recesses, formliner designs, and thin-set brick.

Photo via The Workmans/Aerial Tallahassee

Solid Panels

These panels can be both load-bearing and non-load-bearing but cannot achieve as advantageous thermal efficiency as an insulated panel. These panels are precast concrete and are at least 6″ thick. Reveals, articulation, finishing touches, and mix designs are available to satisfy all your design requirements.

Photo via GATE Precast Company

The precast panels used on the L. Gale Lemerand Student Center were designed to look like the locally quarried Coral or Coquina Stone. Precast achieved this unique natural look while being more affordable, providing a faster installation, and giving increased durability over other construction materials.