Concrete masonry units (CMUs), often known as “concrete block walls,” were traditionally used to construct concrete walls. Today, solid wall panels are often built using precast walls in a controlled environment to fulfill industry standards. In contrast to block walls, precast concrete is poured into precise forms in advance and then transported for a speedier installation than traditional on-site construction.

Various forms and wall types can be included in precast concrete wall systems. They may be used on various structures, from residential to commercial, institutional to industrial, and can be panelized and built in either a horizontal or vertical position.

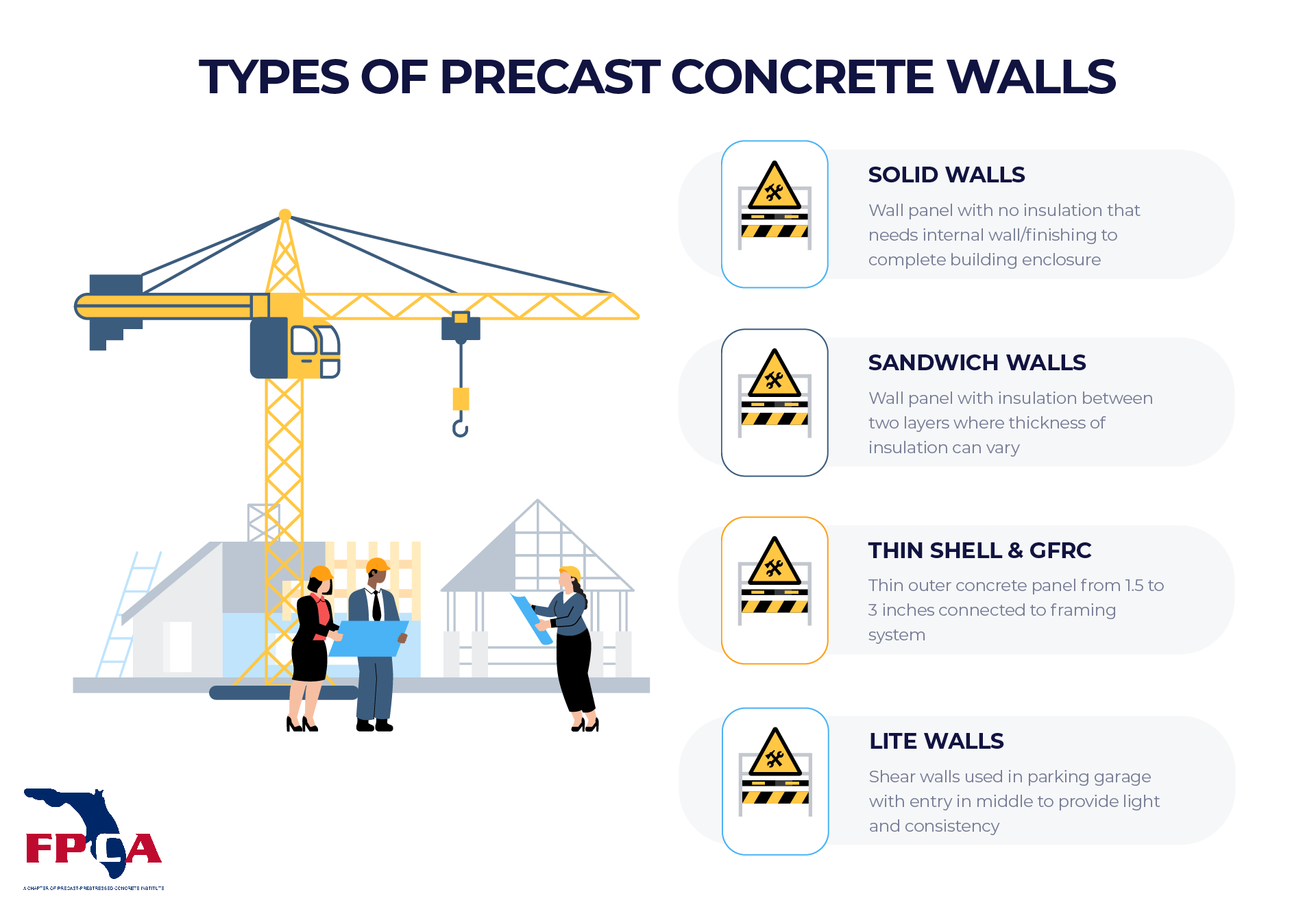

Types of Precast Concrete Wall

Solid Walls

When a wall is described as a solid wall panel, no inherent insulation is present. These walls also need insulation and an internal wall/finishing system to finish the building enclosures. The form side is often the side that will be seen in the finished building since wall panels are cast in a flat orientation. It is possible to create this face with almost any kind of finish. The rear face is frequently smoothed with a trowel, or it might have a light brush finish.

Sandwich Walls

Sandwich wall panels with insulation might be structural, architectural, or both. Insulated sandwich wall panels are cast with rigid insulation “sandwiched” between two layers, or wythes, of concrete, as opposed to conventional panels, which are not. To provide the wall with the necessary R-value for thermal insulation, the thickness of the insulation can be changed.

Insulated sandwich wall panels can support floor and roof elements and be load-bearing. Precasters produce the perfect structural component for this application by typically casting a thicker internal wythe to offer the required support. For a façade, they can also be non-loadbearing.

The panels are cast in a flat orientation, similar to ordinary wall panels, thus the form side is frequently the side that will be seen in the finished building. Again, almost any finish may be used to create this face which is usually troweled smooth or brushed with a faint brush finish.

Thin-Shell and GFRC

A thin, outer-wythe of concrete with a usual thickness of 1.5 to 3 inches makes up thin-shell wall panels. This is linked to a backup system, which is frequently made of steel studs or framing but can also be made of concrete. The backup system joins the wall panel to the building’s structural framework and frequently provides the furring needed to attach interior finishes like drywall. Several of these systems also allow for the addition of a solid insulating layer in the space between the outer concrete wall and the backup system.

Glass fiber-reinforced concrete (GFRC) is a thin-shell technique in which alkali-resistant glass fibers are sprayed into forms and incorporated into the concrete’s external wythe. The fibers boost impact, flexural, and tensile strengths. Comparatively to other precast wall systems, both thin-shell methods decrease the weight of the panels. Some can be made to be load-bearing as well.

The panels are cast in a flat orientation, similar to ordinary wall panels. It is possible to create a face with almost any kind of finish. Great aesthetic elements and additions, such as cornices, are possible with GFRC panels.

Lite Walls

Light or “lite” walls are shear walls used in parking structures that include an entry in the middle to provide visual consistency and let natural light or artificial lighting into a space more deeply. Lite walls offer transparency and a sense of safety, contrary to “light wells,” which are inside open courtyards intended to bring daylight into the heart of parking structures and other buildings.

Lightweight walls are cast horizontally, with a form being used to generate three of the four sides. This produces exceptionally smooth coatings and frequently stays in the completed building “as cast.” Usually, the fourth side is troweled to closely resemble the previous three sides.

Types of Connections in Precast Concrete Walls

Bolted Connections

The bolted connections are the simplest and quickest way to create structures. Last-minute alignment and correction can be done afterward without using valuable crane time. Using the materials recommended by the designer, the bolts must follow the erection drawings.

Welded Connections

The most frequent and usual connection utilized in constructing precast concrete is the welded connection. These connections adapt readily to changing field conditions and are architecturally effective. A loose plate is often sandwiched between two structural steel plates immersed in the cast-in-place or precast concrete panel and then joined by welding.

Dowel/Anchor Bolt Connections

With a dowel connection, the bond formed, embedding length, and dowel diameter all affect how strong the dowels are under tension or shear. The foundation’s exposed threaded anchor bolts and rebar anchor dowels form the crucial initial connection to the precast components.

Structural Design Aspects

Precast walls are intended to serve as a load-free facade or blind divider. Precast walls must, in any case, resist the parallel loads that their own weight, wind, and earthquakes have placed on them.

Evaluating the walls’ planning, specification, and construction is essential to avoid placing unwelcome pressures on precast walls. The design phase should consider loads such as erection, effect, development-related, and transportation of the precast walls.

The seams between the walls must be broad enough to accommodate warm extension and changing seasonal changes. An optional line of defense against water penetration into the building is provided by the divider hole space and go down divider that are protected with a water-safe film.

Characteristics of Precast Concrete Walls

Thermal Resistance

Precast walls can perform in cold weather mainly from the amount of insulation placed inside the reinforcing divider, which is often a metal stud wall.

Maintainability

Because precast walls are made of concrete, they require no upkeep. Regular maintenance can be needed for the anchorages, connections, sealants, and accessories used in precast walls.

Fire Safety

Concrete, a good fire-resistant material, is used to create precast walls, so they inherently have fire resistance.

Acoustics

A precast wall with a veneer will provide comparable performance in terms of sound transmission of noise from outside the building to the inside.

Durability

Precast walls share the same durability characteristics as concrete. In any case, the connections created with the structural part affect their durability. Any abnormalities in the member can be fixed by sandblasting, corrosive washing, hedge pounding, or other techniques.

Moisture Protection

As the precast walls are not physically connected to the other structural parts, such as columns and beams, moisture protection for the precast walls is of utmost importance. This can be achieved with a joint seal or sealer used in connections and joints to keep moisture out of the structure. Pigmented sealants are used to maintain the homogeneity of precast walls and the sealants.

Advantages of Precast Concrete Walls

Precast concrete offers a variety of advantages, such as increased design freedom, time savings during construction, and increased building profitability overall. Moreover, the material’s strength, adaptability, and durability protect the owner against potential harm and additional expenses.

-

Precast concrete walls serve as thermal storage to postpone and lessen peak thermal loads.

-

The inside surface can be designed as a precast concrete wall, which saves time and money by removing the requirement for separate drywall and stud framing expenses.

-

Precast concrete walls can be employed as load-bearing structures by not requiring an extra structural frame system, saving money.

-

It is possible to design precast concrete walls to be reused for future building additions.

-

Due to the toughness of precast concrete, buildings made with it require little maintenance and can withstand adverse weather.

-

Different aggregates, cements, pigments, and finishing methods can create different precast concrete hues and finishes.

-

Precast concrete wall panels can use a thin brick veneer to create a historic facade.

-

Precast concrete walls can be constructed with textures such as liner forms, artwork, and typography for unusual aesthetic treatments.

-

Precast wall panels can be design with electrical boxes and conduits built into the panels to offer flush electrical fittings on walls that are not to be boxed out.