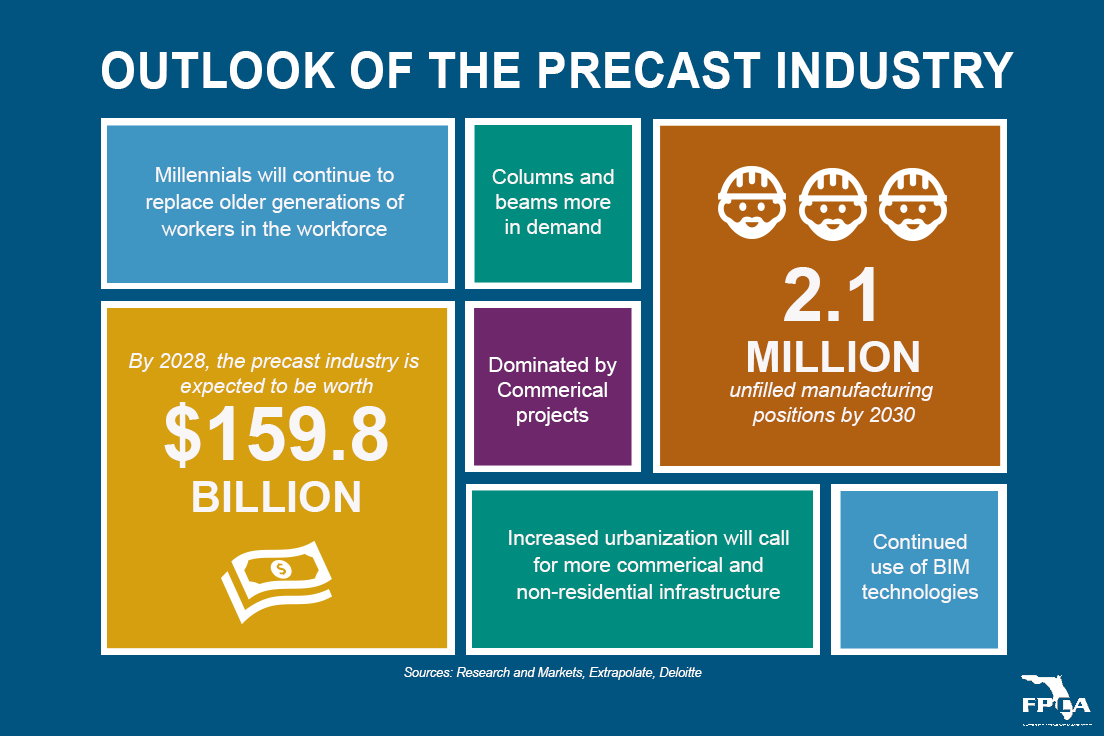

The continuous movement of construction builders and clients toward eco-friendly and economical new building designs is currently driving the market expansion of precast concrete. The precast concrete market was worth $118.4 billion in 2021, and by 2028, it is expected to be worth $159.8 billion.

The precast concrete market is divided by structure systems into beam and column, floor and roof, bearing wall, facade, and other systems. The beam and column system market segment was the largest in 2020. Due to the increasing demand for beams and columns for commercial-purpose buildings, this segment’s market is anticipated to expand quickly during the projected period.

Precast columns and beams are more in demand due to the growing demand for residential constructions through rapid urbanization and increased public and private investment in infrastructure projects, particularly in emerging countries like APAC, South America, and the Middle East.

The precast concrete market can also be divided into residential, commercial, and other segments based on end-use. The market was dominated by the commercial segment in 2020. Due to rising expenditures in new commercial infrastructure projects, this segment’s market is projected to expand quickly throughout the forecast period.

Precast Industry Growth Contributors

Increased Infrastructure Spending

A predicted rise in infrastructure investment is one of the major drivers driving the precast industry’s explosive expansion. Research indicates that an increase in public infrastructure spending would favor the economy, and it is one of the few political topics still supported by both parties in the US. Therefore, it makes sense to anticipate significant federal and state expenditures on large-scale infrastructure during the following years.

New Technologies

The development of new technologies enhancing the speed and efficiency of infrastructure projects is another driver driving the growth of the construction industry and, by extension, the precast concrete market. Greater architectural precision is now possible thanks to technologies like building information modeling (BIM), which also dramatically lowers the number of errors and thus lowers expenses.

Modern technology also contributes to a more ecologically friendly structure. New cooling techniques are being developed to lower the heat of hydration during concrete production drastically. Radical new green materials are also being used in combination with concrete to construct structures.

Increased Urbanization

The precast market is also expanding due to rising urbanization, industrialization, and electricity generation capacity. Demand for commercial and non-residential infrastructure is increasing as urbanization and digitization spread worldwide. These elements are causing the precast concrete market worldwide to expand. Precast concrete use is anticipated to accelerate, and new market opportunities will be created by increased expenditures in non-residential projects from industry participants.

What The Precast Industy’s Outlook Means for Workforce Development

Precast allows projects to be finished in less time and cheaper than conventional, on-site processes for creating concrete buildings. This is one of the reasons it has benefited particularly from the boom in general construction. Precast components are not built outside, making them less prone to environmental influences like dampness and pollution.

Although the labor scarcity in the construction industry is nothing new, it has gotten much worse over the past few years. More and more workers are reaching retirement age as the sector ages. The fact that there will be more than 2.1 million unfilled manufacturing positions by 2030 in the US is a current worry of precast concrete producers. In the upcoming years, strategies employed over the previous 20 years to locate workers for the factory floor will need to be updated.

Millennials, a new generation that has been molded not just by the introduction of technology but also by the rate at which it is developing, will continue to want to work for innovative firms. Effective strategic workforce planning may assist businesses in identifying enhancements to their human resource practices that complement their overarching business strategy.

Due to unpredictable scheduling and rigorous labor, the generation entering the workforce is avoiding the construction sector. However, the precast concrete industry can resolve the main issues in the construction sector. Precast concrete requires a smaller staff because most work is done off-site. A smaller workforce also implies that fewer trades must be trained in a precast concrete environment.

Each worker in a precast concrete environment is also an expert in their particular expertise. Precasters don’t visit various locations and work on a range of projects. Instead, they focus solely on a specific element of a precast concrete building.

This means that workers in the precast industry can expect specialized training for their positions and the chance to work with new and innovative technologies being created daily. They also will benefit from working closely with a team of peers dedicated to constructing everything from mega structures to the bridges their friends and families use daily.

Key Takeaways

The precast industry is expected to continue to grow well into the future around the world. Precast manufacturers can tackle the growing workforce shortage issue today by teaching potential employees the benefits of precast and how fulfilling a career in the precast industry can be.